- Out-of-Stock

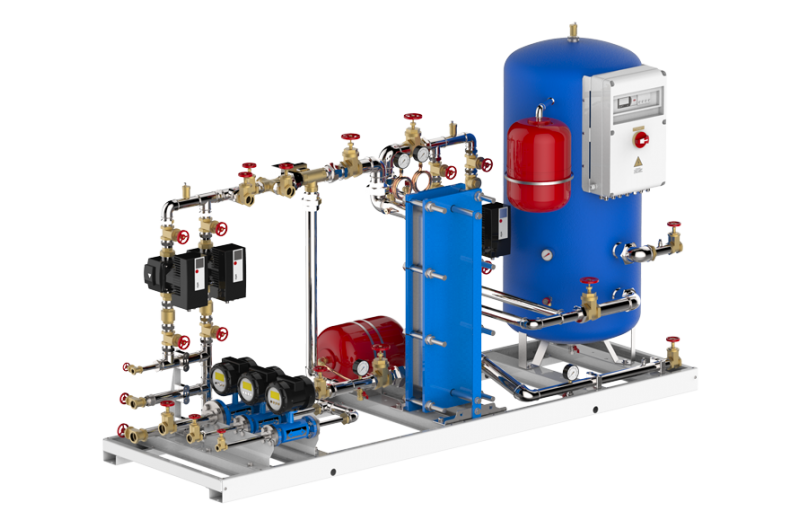

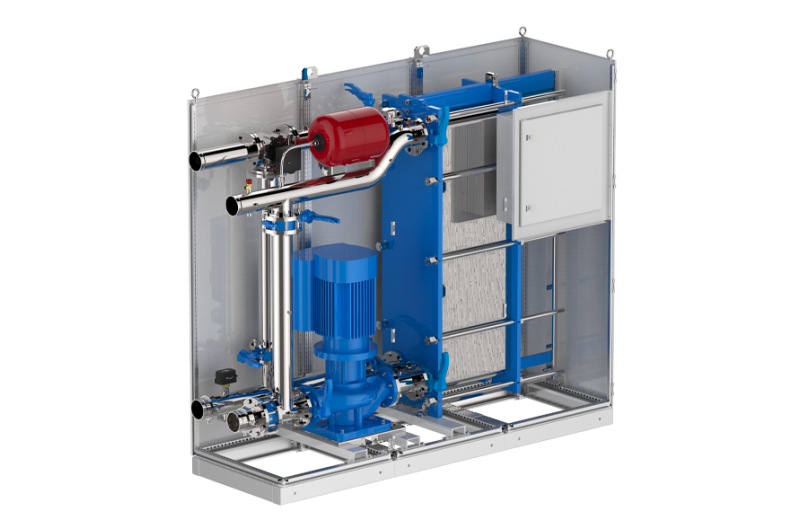

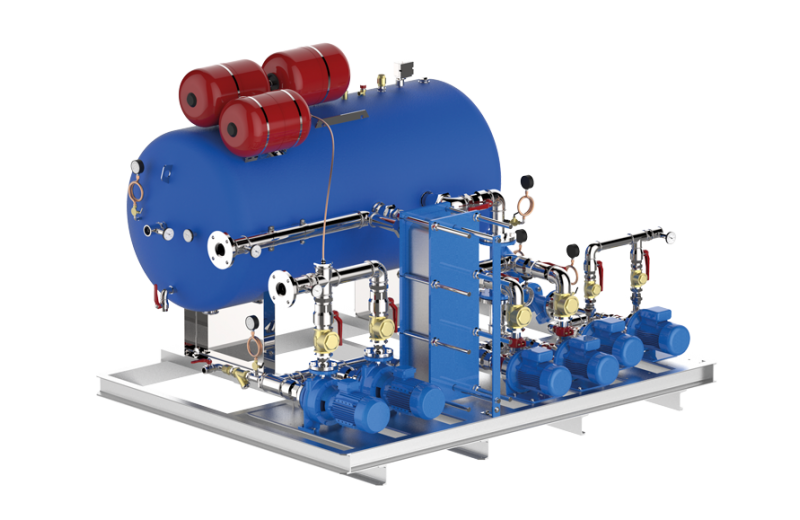

The HS-BT groups have been specifically designed to optimize the performances of industrial cooling systems and to reduce installation times. The units constitute an integrated system, complete with all the components necessary for the efficient operation of the hydraulic circuit or for the distribution of chilled water. Each group is designed, pre-assembled and tested in the factory. This guarantees greater quality in the execution of the systems and simpler and quicker installation. The kits are available with a wide range of pump/accumulator/exchanger combinations functional to any type of refrigeration system. The groups can be customized based on specific use needs and installed internally or externally.

Single or double centrifugal pump, vertical or horizontal, with shut-off valves, made of cast iron with stainless steel impeller. Each pump can be controlled by an inverter (optional).

Vertical or horizontal tank, available in galvanized, stainless steel or Teflon-coated steel versions and pipes insulated with anti-condensation elastomer. The tank can be supplied with an automatic filling system both in an open and closed execution (both optional).

The groups can be customized by including a brazed plate or shell and tube heat exchanger, both of them inspectable.

Electric power panel with pump alternating device at each start-up (version with 2 pumps), spare pump start in case of pump failure (version with 2 pumps), magnetothermic protections, clean contacts for remote signaling of pumps running.

• Programmable start-up for pump alternation: in the double pump configuration, the timer can be used to manage the alternation in the working pump, at specific time intervals.

• Anti-vibration feet: to be placed in the support points of the machine (supplied loose).

• Inverter: each pump can be managed by an inverter. The units equipped with inverters are provided with a pressure sensor, 0-10 bar, which communicates with the inverter via a 4-20 mA signal. All parameters are set during the testing phase.

• Antifreeze electric resistance kit: the kit, mounted inside the tank, consists of one or two electric heaters (functional to the volume of the tank) controlled by an anti-freeze thermostat.

• Mesh filter: installed on the return pipe.

• Valves for pressure control: connected externally, they allow the circuit to be balanced.